Great Technology Needs Great Minds

Xihelm isn’t just a company; it’s a collective of luminaries set on reshaping the agrifood landscape. Comprising engineers, PhD researchers, and computer scientists, our team is guided by dual missions:

- Crafting the Quintessential Robotic Harvester: Designed to excel in greenhouse environments, our robotic harvesters redefine efficiency and precision.

- Deploying End-to-End Automation Solutions: From the fields to the packhouse, we are developing a versatile AI system capable of automating a range of complex agricultural tasks.

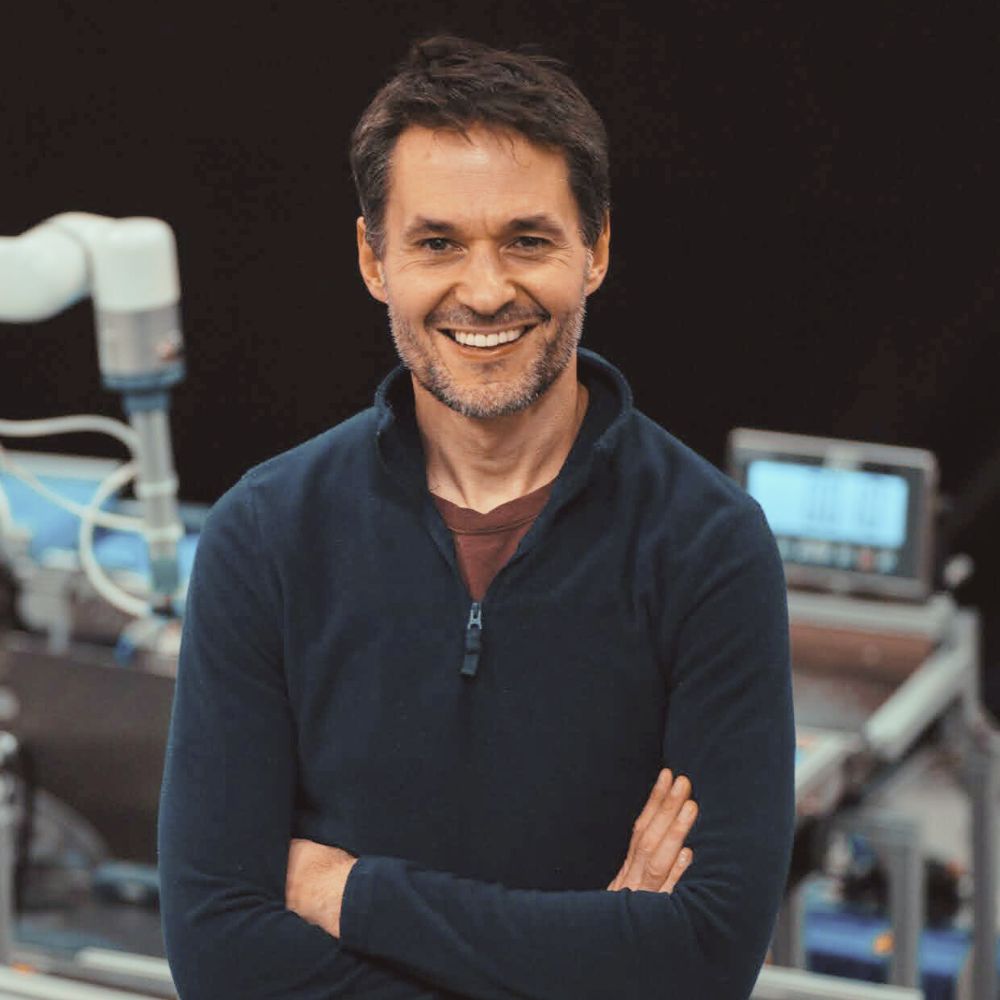

James Kent

James has a firm pedigree in innovation. Having filed no less than 16 patents during his five years at Google, his multidisciplinary approach has led and informed Xihelm’s rigorous R&D programme, keeping the team ahead of the competition and capturing the attention of agri-tech investors.

Niall Healy

As the former Commercial SVP at proSapient, Niall excels in scaling VC-backed startups and driving revenue growth. Now as COO and Chief of Staff at Xihelm, he applies his operational and commercial expertise to streamline processes and attract investment, ensuring Xihelm stays at the forefront of the agri-tech industry.

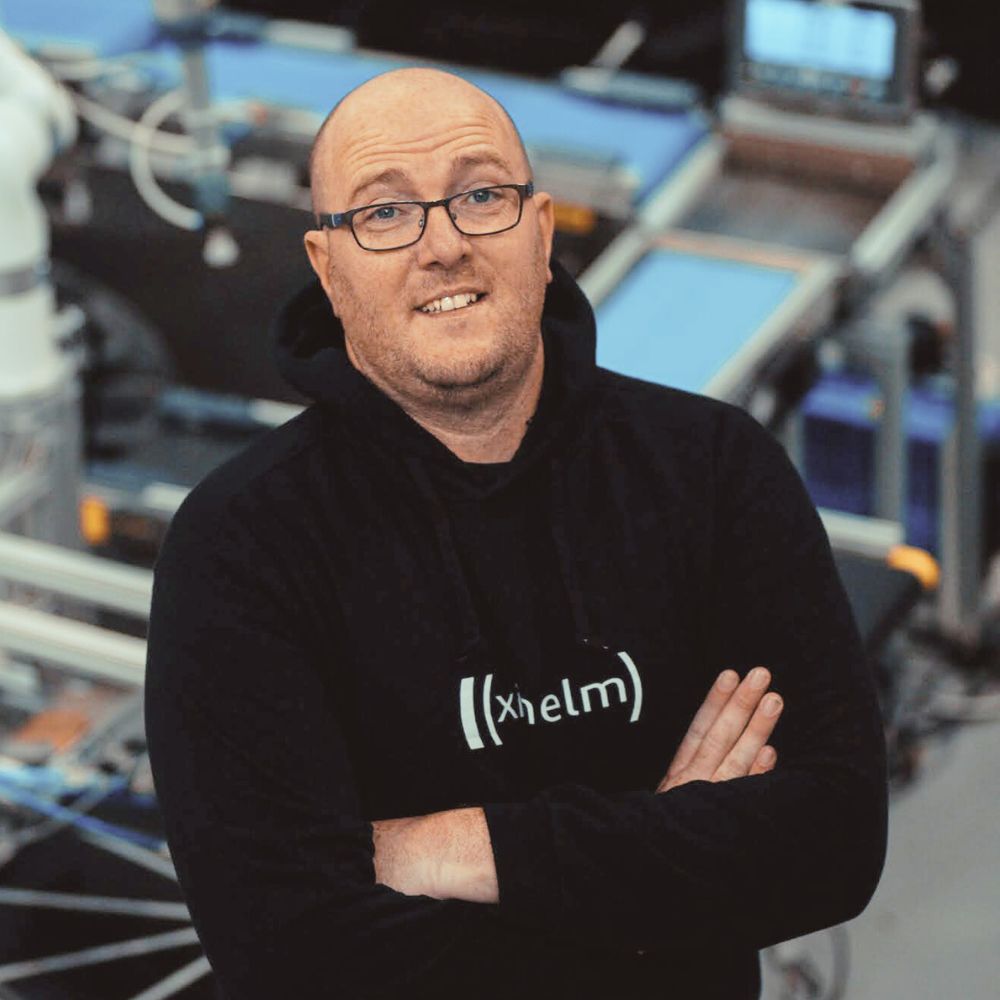

Darren Blair

During nearly four years at Xihelm, Darren (or ‘Dash’, as he’s known) has been responsible for the deployment of Xihelm’s autonomous robots across multiple partner grower sites. Dash’s role also includes managing trials, field experiments, new operator training and overseeing the operations of all customer sites.