Revolutionising Agrifood with

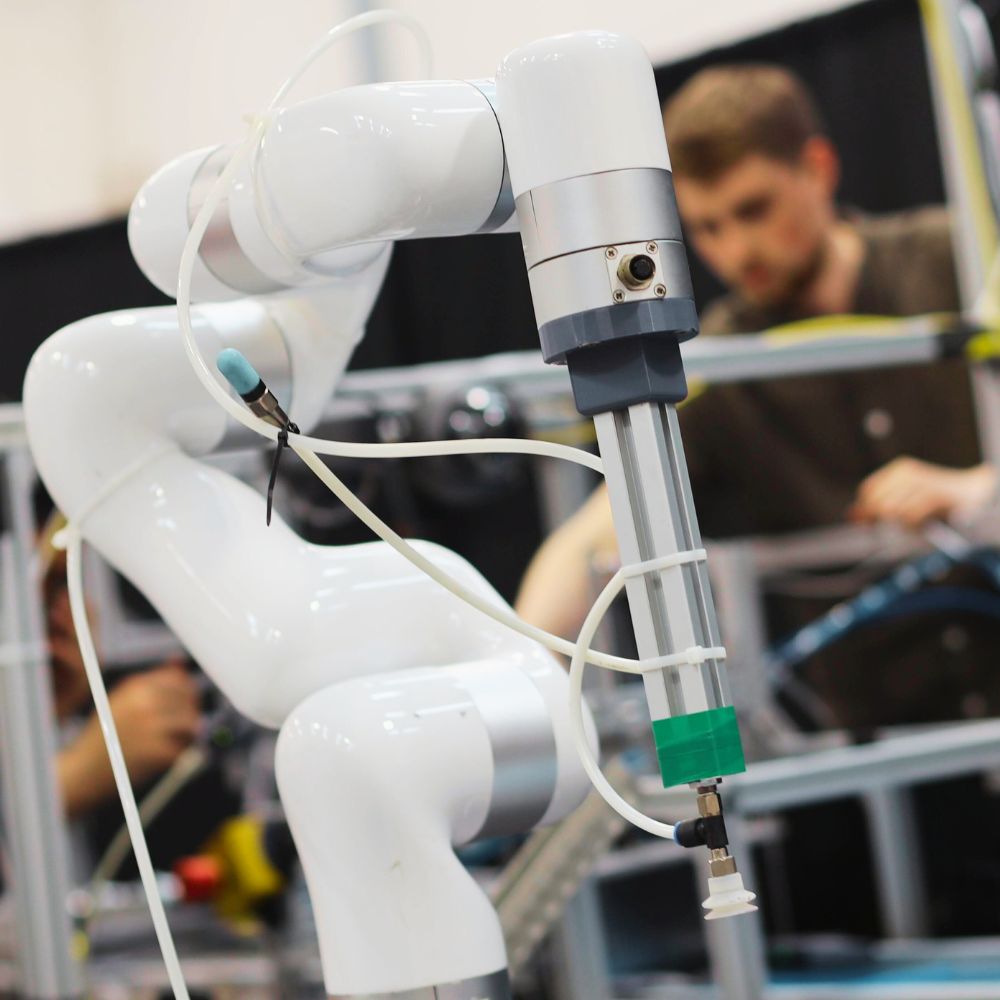

At Xihelm AI, robotics, and mechanical engineering converge to transform agrifood. We automate delicate tasks like tomato harvesting, revolutionizing farming efficiency. Join us in shaping a sustainable, resilient future for agriculture.

Why Xihelm?

We’re not just changing farming – we’re sculpting its future through the seamless fusion of AI, robotics, and mechanical ingenuity. Our goal? To choreograph the automation of intricate tasks, like the gentle art of tomato harvesting.

Powered by Advanced AI Datasets

Since 2017, our 3D AI data engine has fueled our Eagle robot for sevenfold faster harvesting. AI detects crop disease early, ensuring healthier yields. Our Robots as a Service (RaaS) model offers comprehensive grower solutions.

Designed by Experts

Engineers, PhD researchers, and computer scientists collaborate at Xihelm. We bridge tech and agriculture, propelling innovation beyond limits.

Refined by Industry Experts

Partnering with UK and Netherlands growers, we refine solutions practically. Our tech isn’t just visionary—it’s field-tested and approved.

Distinctive Advantages, without Comparison

Unlike competitors, Xihelm emphasizes efficiency and reliability. Off-the-shelf robot arms showcase our commitment to dependable impact.

Addressing the Unaddressed

Xihelm redefines harvesting and packing. Elevating quality and sustainability with our game-changing automation technology.

Patented Innovation

Backed by patents, our solutions are at the forefront of agritech innovation. Solidify your future with Xihelm’s pioneering tech.

Curious to Know More About How We Are Using AI in Agrifood?

Discover how AI revolutionizes agriculture—making it sustainable, efficient, and resilient. Join us in shaping the future of agrifood.